Horizontal barrier

Horizontal barrier from HW-Mauerrockenlegung

The permanent and chemical-free solution against rising damp in walls: an HW horizontal barrier. We would be happy to advise you in detail about our products and find an HW partner near you!

Details

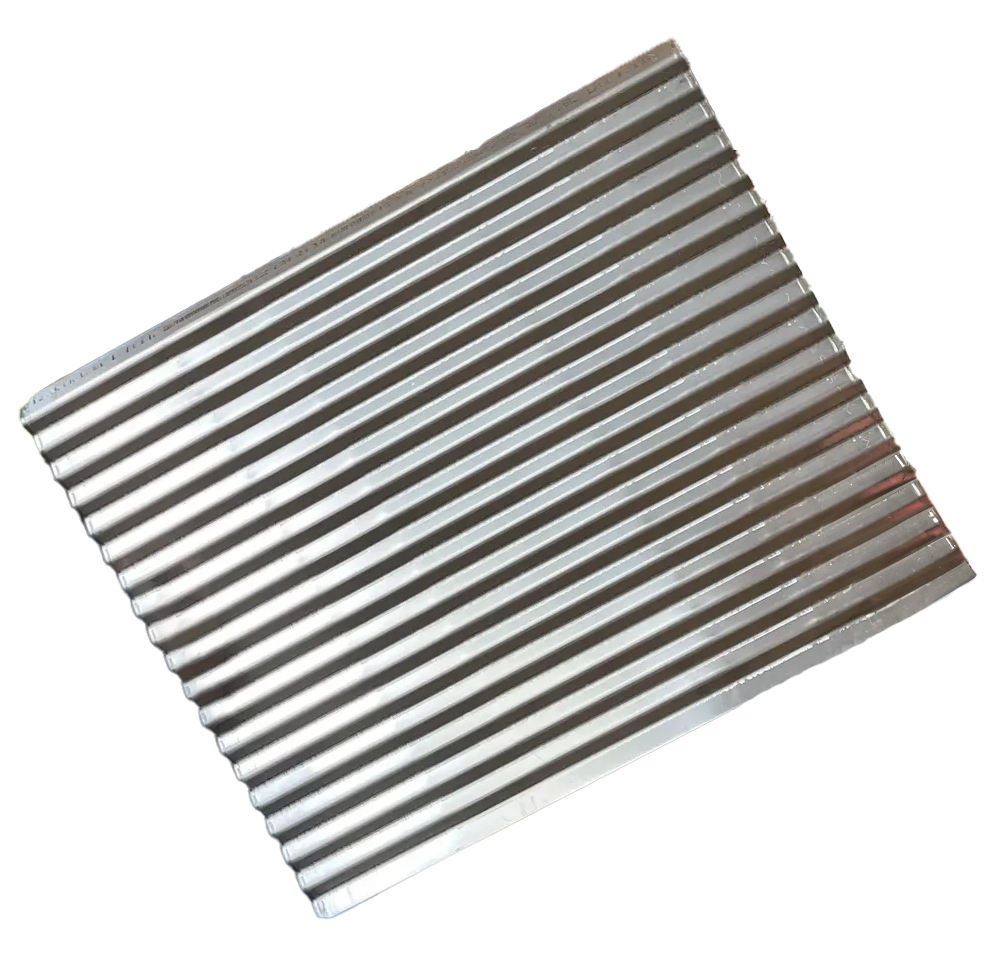

- Material: Chrome steel, chrome-nickel steel or chrome-nickel-molybdenum steel

- Dimensions: Depending on material & design: 310 or 375 mm width, 120 to 1000 mm length

- Price: On request

- Possible applications: All buildings with continuous bed joint

- Chrome steel plates with the HW tip: The point at the front edge of the panels results in less friction on the panel surface when driving in, which means less energy is required and therefore a gentler insertion into the masonry. The compaction of the joint compound above and below the barrier layer prevents settlement cracks.

- Maintenance-free, effective and gentle on walls

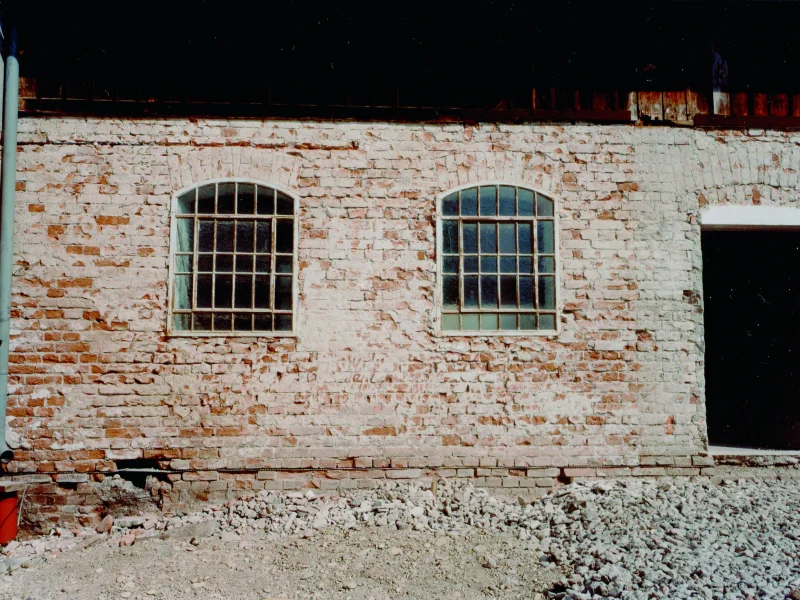

HW horizontal barrier - the effective solution for damp walls

Musty smell, peeling plaster or even mold in the cellar or living area? Then you most likely have damp walls and should act immediately.

HW wall drying has a absolutely safe process that protects masonry from rising damp and thus ensures permanently dry walls. We offer you patented stainless steel panels, which are manufactured by our partner companies in Germany, Austria and Switzerland., Czech Republic and other European countries as subsequent horizontal barrier can be installed in walls to mechanically interrupt the rise of moisture.

The advantages at a glance:

- Permanent solution against rising damp

- Cutting and sealing in just one operation

- Retrofitting possible

- Protects the building fabric

- No boreholes, no chemicals

- Suitable for exterior and interior walls up to 1 m thick

- Increase in the value of the property

- Effective even with heavily soaked or already damaged walls

- Can also be used for basement waterproofing in combination with an intact vertical barrier

How to ensure permanently dry walls

Wall moisture is indicated by signs such as peeling plaster, salt efflorescence, dark stains and mold growth. We have summarized all the signs here:

Get in touch with us and we will put you in touch with our licensee in your area. If you prefer, you can also contact our licensees directly.

Our HW partner installs our indestructible HW horizontal barriers in your masonry. Installation takes place in just one work step and is therefore time-saving, effective and gentle on the masonry.

Once the wall above the barrier has dried out, the exterior of the wall can be renovated (plastering and painting). The horizontal barrier provides permanent protection and requires no maintenance!

Reviews & References

HW-Mauerrockenlegung has been ensuring permanently dry walls for 50 years - in Germany and Europe. Our work speaks for itself. Get an overview of our projects and see for yourself.

Become an HW partner

Are you a trade business or construction company and would like to dry out walls using the HW method? Get in touch with us to request further information and become an HW partner.

HW stainless steel plates

As an HW partner, you may use licensed HW stainless steel plates for wall drying. The patented HW steel plates can be purchased from us in the desired quantity.

HW impact devices

The panels are driven in with a HW impact device which, in combination with our panels, enables them to be driven in without damaging the wall. This can be purchased from us as a partner.

Technical know-how

If you have decided toto want to work with our HW system, you will receive practical training and detailed instructions on technical implementation.

Questions and answers about horizontal barriers

What is a horizontal barrier?

A horizontal barrier is a structural measure that prevents moisture from the ground capillary into the building. the wall of a building rises. In new buildings, horizontal barriers are installed in accordance with the current state of the art; in old buildings, they can be integrated retrospectively. The aim is to minimize the capillary effect of the masonry. complete to interrupt and to prevent mold growth, salt efflorescence and structural damage (crumbling plaster, broken bricks) and to create a pleasant indoor climate.

The HW process uses specially shaped stainless steel plates that are particularly robust and durable and can be driven in without damaging the wall. Chemical injections, boreholes or sawing open of the walls are This makes our method unique, environmentally friendly and gentle on walls.

How does the HW process work?

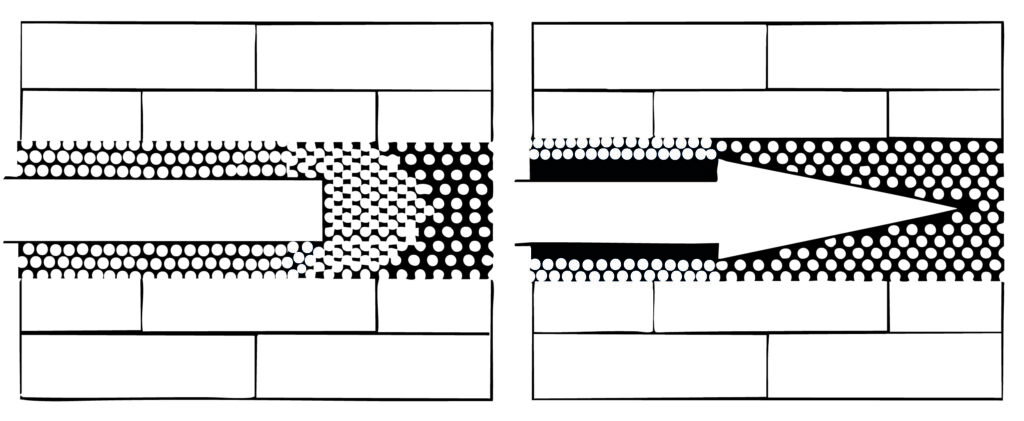

We at HW-Mauertrockenlegung enable our professional partners toto use the patented HW process. The following are used 1.5 mm thickrust- and acid-resistant stainless steel plates, which are gently inserted directly into the Mortar joint of the masonry be collected. In this way, complete moisture insulation is achieved in just a single work step (separating & sealing).

Our corrugated, overlapping stainless steel panels form a permanently tight, horizontal barrier against capillary rising damp. Due to the arrowhead-shaped front edge of the insulating panels is the impact resistance is greatly reduced by reducing the surface friction. Shocks and vibrations are thus reduced and damage to the building fabric caused by driving in the panels is avoided. As no masonry is removed during driving, there can also be no subsidence.

This technology enables a Driving the panels into masonry up to 1 m thick from one side!

How do damp walls develop?

There can be various causes for a damp wall. In addition to existing leaking sealing systems, the most common cause of damp in masonry is the lack of a horizontal barrier against rising ground moisture in the foundation walls.

The water seeps out of the ground into the wall and is transported upwards by the capillary effect. When the salts dissolved in the water evaporate, they form crystals on the wall surfaces, causing mortar and wall paint to flake off. Staining on the wall, crumbling plaster and a musty indoor climate are the consequences and reduce the quality of living enormously.

When is a horizontal barrier necessary and sensible?

Are you noticing signs of moisture in the walls? Then it is very likely that the horizontal barrier is missing or defective. In old buildings in particular, there is often no or only an inadequate moisture barrier, which is why you will benefit from a retrofitted horizontal barrier.

The HW horizontal barrier made of stainless steel plates is suitable for all types of masonry where there is a continuous bed joint. The horizontal barrier also has an excellent effect on heavily damp or already damaged walls.

The precise insertion of the stainless steel plates creates a durable and robust barrier that interrupts the capillary effect and reliably stops rising damp. Our solution is ideal for old buildings, listed buildings and walls with a high moisture load. If the vertical barrier is sufficient, HW horizontal barriers can also be used for basement waterproofing. The process is gentle on the building fabric and enables your walls to be permanently dried out.

How is the HW stainless steel barrier installed?

While many new buildings usually have a horizontal barrier, this is not the case for a large number of old or existing buildings. These either have no horizontal barrier or one that is already inadequate. Our patented, mechanically installed horizontal barrier is the ideal choice for subsequent waterproofing against capillary rising Humidity.

Our products and the special method of driving them into masonry are unique in their entirety. By means of our pneumatic HW impact devices, with which we drive the HW stainless steel plates into the wall, we carry out the subsequent wall drying in just one single step!

Is a HW horizontal barrier also suitable for waterproofing basements?

Our HW partners will assess whether our method is suitable for your cellar - or other walls in your building - on site. The cause of damp in the brickwork in the cellar is usually not only the vertical rise, but also the lateral penetration of moisture from the surrounding soil. When renovating a cellar, a horizontal barrier only makes sense in combination with an intact vertical barrier. It should be noted that the horizontal barrier must be installed first, before the vertical insulation is installed.

It is best to seek advice on basement waterproofing from a specialist company.

Contact us and get advice

Do you need individual advice or do you have questions about our horizontal barriers? Please contact us! We will be happy to inform you about your options and recommend HW partners in your area.

Other methods for drying walls

We are convinced that the problem of rising damp can only be permanently and effectively eliminated by a mechanical barrier. This is because only mechanical processes form an absolute moisture barrier. Professionally installed, they are comparable to a new building. As the tightness can be proven, they are among the structurally safe methods.

Here you can find the Two-stage wall cutting/sawing process and Our single-stage HW process (Cutting and sealing is done in one step).

The Wall sawing/cutting process is used if there is no continuous bed joint in the wall to allow the HW stainless steel plates to be driven in or if the design of the joint (too narrow or too hard) does not allow the HW stainless steel plates to be driven in. Due to the relatively large impact on the stability of the masonry, only short sections should be sawn open and sealed as quickly as possible, supported with wedges and the joint grouted again.

For the sake of completeness, we present other methods that are currently used to protect against vertically rising damp.

Other mechanical processes

Continuous drill cores are taken from the masonry. The row of drill holes is then filled with dense material. Due to the number of drill holes required and the use of diamond bits, this method is very expensive and is rarely used anymore.

In the wall replacement process, heavily damp or damaged sections of masonry are removed in sections and replaced with new masonry with an integrated horizontal barrier.

In view of the considerable intervention in the building fabric and the weakening of the structure, advice and support from a structural engineer is required.

Chemical and electro-physical processes

Injection

This chemical process is intended to create a water-repellent, capillary-blocking zone by the targeted injection (unpressurized or pressurized) of hydrophobic, capillary-constricting agents into the masonry. In practice, it has been shown that the effect depends heavily on the condition of the wall (moisture content, porosity, salt load, proportion of joints). Absolute proof of impermeability is not possible in practice.

Silicification

Silicification is a chemical method for subsequent wall drying. Aqueous silicic acid solutions or silicates are introduced into the wall via drilled holes. This can reduce capillary water transport. As with injection, the effect depends heavily on the condition of the masonry. Absolute proof of impermeability is not possible here either.

Electroosmosis

In this electro-physical process, the capillary rise of the pore water is to be influenced under the influence of a direct current field and pushed towards the ground. The practical functioning of this method on damp masonry is still unclear and the method is highly controversial in technical circles.

Our 50 years of experience in the field of wall drying have shown us that mechanical methods are an absolute moisture barrier and chemical methods are a relative moisture barrier.

Difference between the horizontal and vertical lock

The big difference between horizontal and vertical The horizontal sealing of the walls prevents the vertical capillary rise of soil moisture in the masonry. Vertical waterproofing, on the other hand, prevents moisture from penetrating into the area of the side walls in contact with the ground and is relevant, for example, for basement waterproofing and the damp-proofing of other underground structures. Vertical barriers can - depending on the circumstances - be installed internally or externally, whereby an external vertical barrier is preferable.

HW wall drying - Say goodbye to damp walls!

The HW Mauertrockenlegung process offers you a dense, verifiable, Permanent and maintenance-free measure to combat damp walls. Are you interested? Then get in touch with us and let us advise you personally.